M1.4 Screw Torx sheet metal Screw emnyama eyenziwe ngegalvanized

Inkcazo

Izikrufu ezincinci zeTorx ziziqhoboshi ezincinci ezibonisa ukuchaneka kwenkqubo yeTorx drive kubungakanani obubambeneyo.Njengomzi-mveliso okhokelayo ohamba phambili, sisebenza ngokukhethekileyo ekuveliseni izikrufu zeTorx ezikumgangatho ophezulu ezibonelela ngokusebenza okubalaseleyo kunye nokuthembeka.

I-M1.4 Screw Torx yethu yenzelwe ngokukodwa usetyenziso apho indawo incinyiweyo okanye isisombululo esincinci sokuqinisa siyafuneka.Ngobukhulu bazo obuncinci, babonelela ngokuqiniswa okuchanekileyo kunye nokukhuselekileyo kwiindibano ezithambileyo nezintsonkothileyo.Ngaphandle kobukhulu bazo obuncinci, izikrufu zethu ezincinci zeTorx zigcina umgangatho ofanayo wokuchaneka njengabalingane bazo abakhulu, ziqinisekisa ukusebenza okuthembekileyo kunye nokungaguquguqukiyo.

Inkqubo yokuqhuba i-Torx, kunye ne-recess emile okwenkwenkwezi kunye namanqaku amathandathu oqhagamshelwano, inika ukubamba okuphezulu kunye nokudluliselwa kwetorque xa kuthelekiswa nezinye iinkqubo zokuqhuba.Izikrufu zethu ezincinci zeTorx zibonisa le nkqubo yokuqhubela phambili, evumela ukuqina okusebenzayo nokuthembekileyo nakwindawo ezixineneyo.Inkqubo ye-Torx drive inciphisa umngcipheko wokuphuma kwekhamera, ukunciphisa ithuba lokuhluba okanye ukonakalisa intloko ye-screw ngexesha lofakelo okanye ukususwa.

Siyaqonda ukuba izicelo ezahlukeneyo zifuna iipropathi ezithile zemathiriyeli kunye nokugqitywa komphezulu.Yiyo loo nto sinikezela ngoluhlu olubanzi lwemathiriyeli kwizikrufu zethu ezincinci zeTorx, kubandakanya intsimbi engatyiwa, intsimbi yealloyi, nokunye.Ukongeza, sibonelela ngeendlela ezahlukeneyo zokugqitywa komphezulu ezifana ne-zinc plating, i-oxide emnyama, okanye i-passivation yokuphucula ukuxhathisa ukubola kunye nobuhle.Oku kuqinisekisa ukuba izikrufu zethu ezincinci zeTorx zinokumelana neemeko ezisingqongileyo kwaye zigcine ingqibelelo yazo ekuhambeni kwexesha.

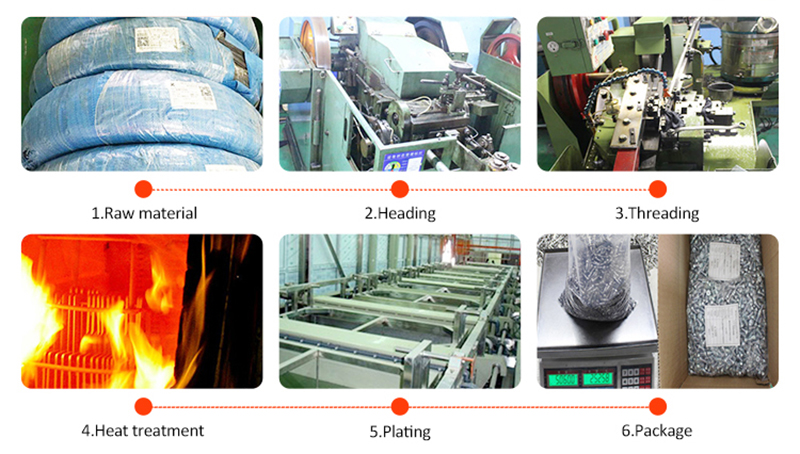

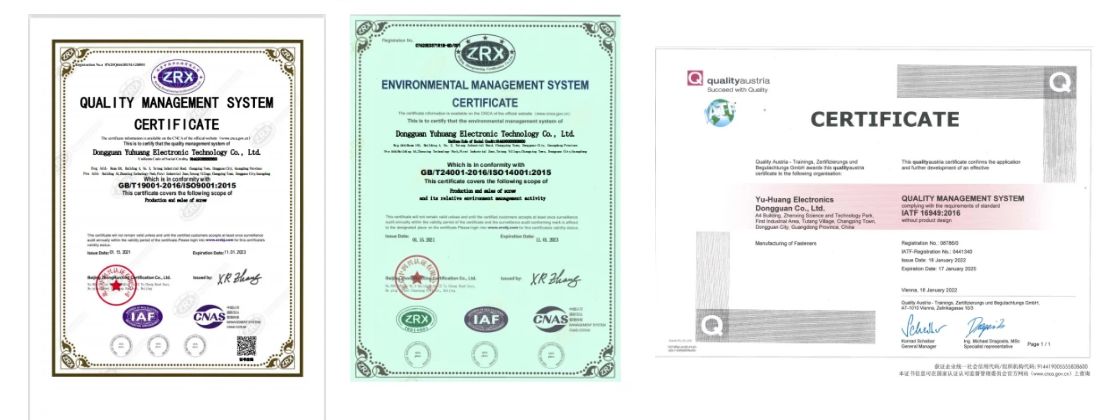

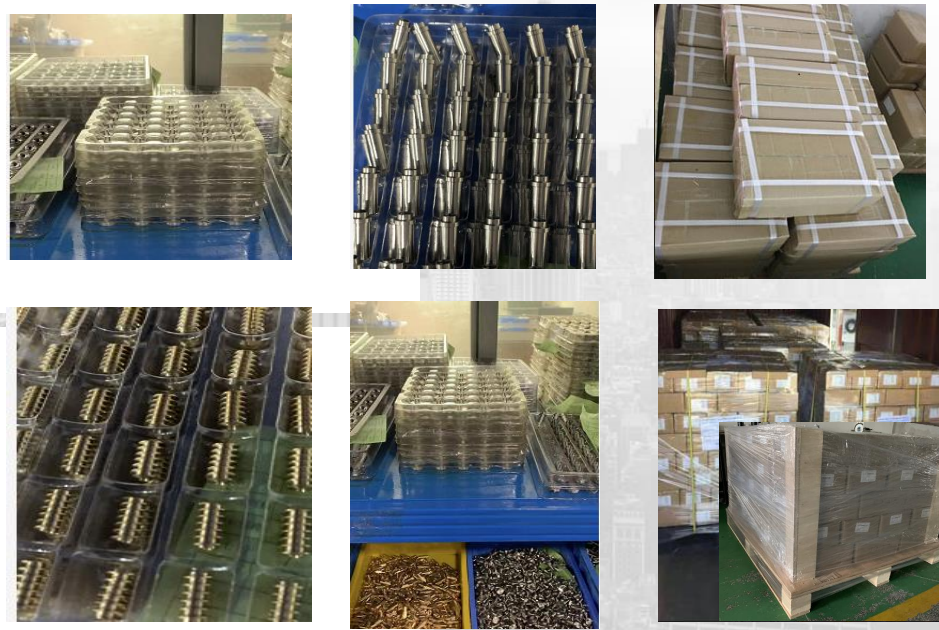

Kwifektri yethu, sibeka phambili ukwaneliseka kwabathengi kwaye sinikezela ngeenketho zokwenza ngokwezifiso ukuhlangabezana neemfuno zakho ezizodwa.Unokukhetha kwiisayizi ezahlukeneyo zomsonto, ubude, kunye nezimbo zentloko ukuze uqinisekise ukufaneleka ngokugqibeleleyo kwisicelo sakho.Sithobela amanyathelo angqongqo olawulo lomgangatho kuyo yonke inkqubo yemveliso, siqhuba uhlolo olucokisekileyo ukuze siqinisekise ukuba izikrufu zeTorx ezineentloko ezintandathu zidibana neyona migangatho iphezulu yokuchaneka nokusebenza.

Izikrufu zethu ezincinci zeTorx zibonelela ngokuchaneka okuphezulu kwisayizi encinci, zisebenzisa inkqubo ethembekileyo yeTorx drive.Ngoluhlu olubanzi lwezixhobo kunye nokugqitywa okukhoyo, kunye neenketho zokwenza ngokwezifiso, sinokubonelela ngezikrufu ezincinci zeTorx ezihlangabezana neemfuno zakho ezithile.Njengomzi-mveliso othembekileyo wokuqinisa, sizibophelele ekuziseni izikrufu ezincinci zeTorx ezingaphezulu kolindelo lwakho malunga nokusebenza, ukuqina, kunye nokusebenza.Qhagamshelana nathi namhlanje ukuxoxa ngeemfuno zakho okanye ubeke iodolo yezikrufu zethu ezikumgangatho ophezulu weTorx.